The fiber volume fraction achieved by this process is greater than 60% and this process is most common in R & D to make flat laminates. In this process, thermoplastic intermediates are stacked together, placed between molds, and consolidated into composites by application of heat and pressure to melt the thermoplastic resin and impregnate the fibrous reinforcement. Glass mat thermoplastics are the major class of products manufactured from this technique.Īnother type of compression molding is the hot press technique in which intermediate thermoplastic materials like prepregs and hybrid yarns are used. The process is used for making bumper beams, dashboards, kneebolsters, and other automotive structural parts. This is the only thermoplastic manufacturing process used in industry for making structural thermoplastic composite parts. Alagirusamy, in Technical Textile Yarns, 2010 12.4.1 Compression moldingĬompression molding of thermoplastic composites is a flow-forming process in which the heated composite sheet is squeezed between the mold halves to force resin and reinforcement fibers to fill the cavity. The temperature of tube billet is 850 ☌, and the optimal processing parameters were obtained. ( 39) numerically investigated the deformation behaviors of the three-roller synchronous hot backward spinning of TC4 tube. Textures in the outer and inner layers evolve differently because of inhomogeneous deformation histories. Large material rotation occurs and many grains are kinked and distorted in the outer layer, especially when thick-wall billet is spun. The study showed an obvious through-thickness inhomogeneity in deformation, microstructure, and texture.

( 38) presented the correlations of microstructure and texture with deformation history in backward tube spinning of Ti–6Al–2Zr–1Mo–1V. The study showed that the forming limit can be improved significantly when the setting temperature is higher than the recrystallization temperature. With a Mg AZ31 tube as the objective, the hot spinning feasibility of magnesium tube and the properties of formed tube over the recrystallization temperature were analyzed ( 37). Deformation History and the Resultant Microstructure and Texture in Backward Tube Spinning of Ti-6Al-2Zr-1Mo-1V. Schematic of backward tube spinning by one roller.

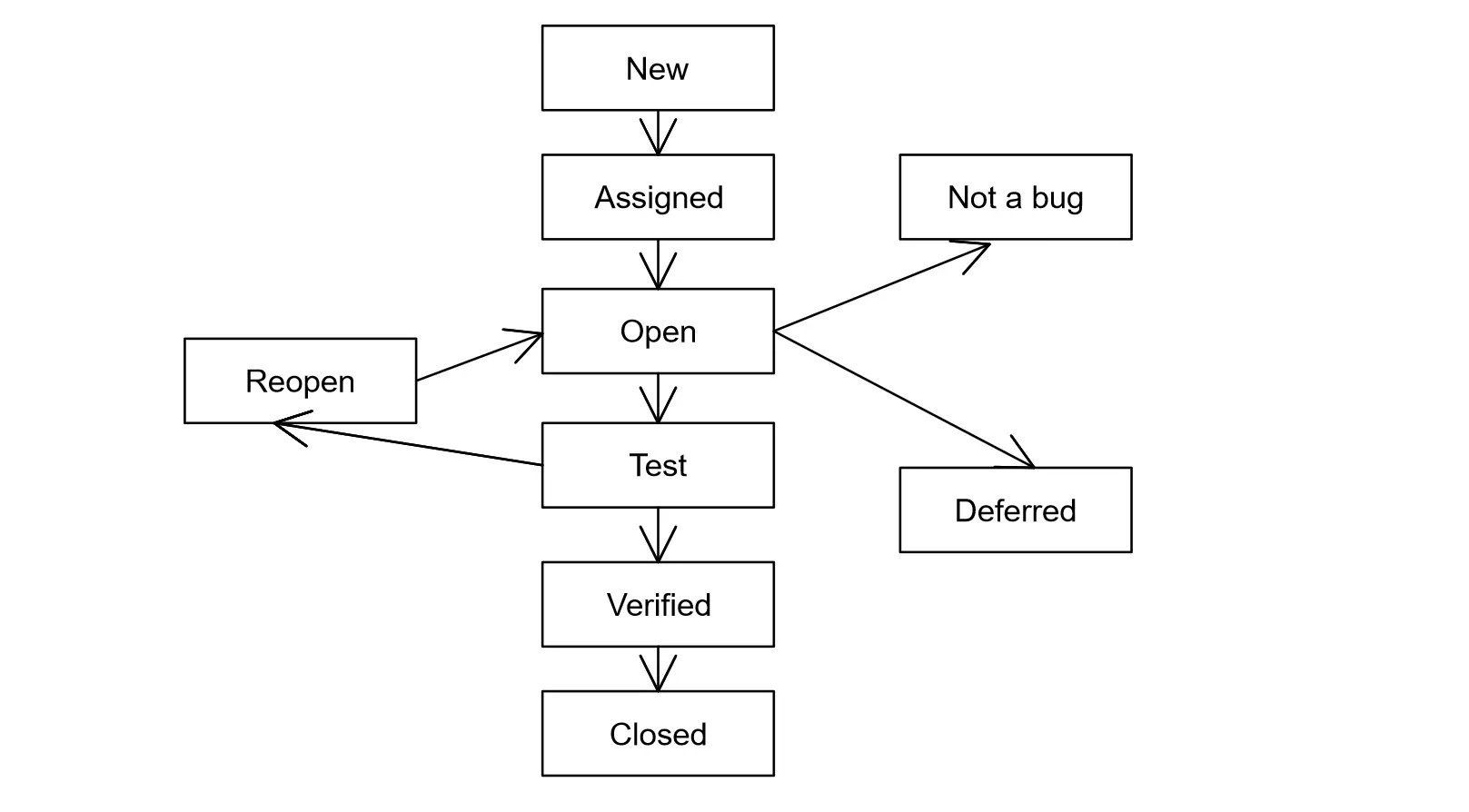

Defect process flow crack#

They found that the GTN model is applicable for predicting the appearance of macroscopic crack in the pile-up region in flow forming.įigure 10. (2016) predicts the damage evolution and fracture in the flow forming of 3A21-O aluminum alloy by integrating the GTN model into FE model. Specially, the Cockcroft and Latham model provides the most accurate predictions. The results indicate that except for the Freudenthal, R-T and Ayada models, Cockcroft- Latham, Oh, Brozzo, McClintock, modified Ayada and LeRoy models are applicable to predict the damage distribution and fracture, as shown in Fig. (2015) evaluated the applicability of different uncoupled DFCs in the flow forming of a TA2 titanium alloy tube at room temperature. According to whether the damage is considered in constitutive model, the DFCs can be classified into two types: uncoupled DFCs (such as Rice-Tracey, McClintock, Oh, Cockcroft-Latham, LeRoy and Ayada models) and coupled DFCs (such as the Lemaitre and Gurson-Tvergaard-Needleman (GTN) models). Its key modelling part is establishing a reasonable fracture criterion, which includes the damage evolution model and corresponding damage threshold value for fracture formation. At present, integrating the ductile fracture criteria (DFCs) into FE simulation is the most popular method to predict the damage evolution and fracture in the flow forming.

0 kommentar(er)

0 kommentar(er)